Manual Production Systems

Manual Production Systems

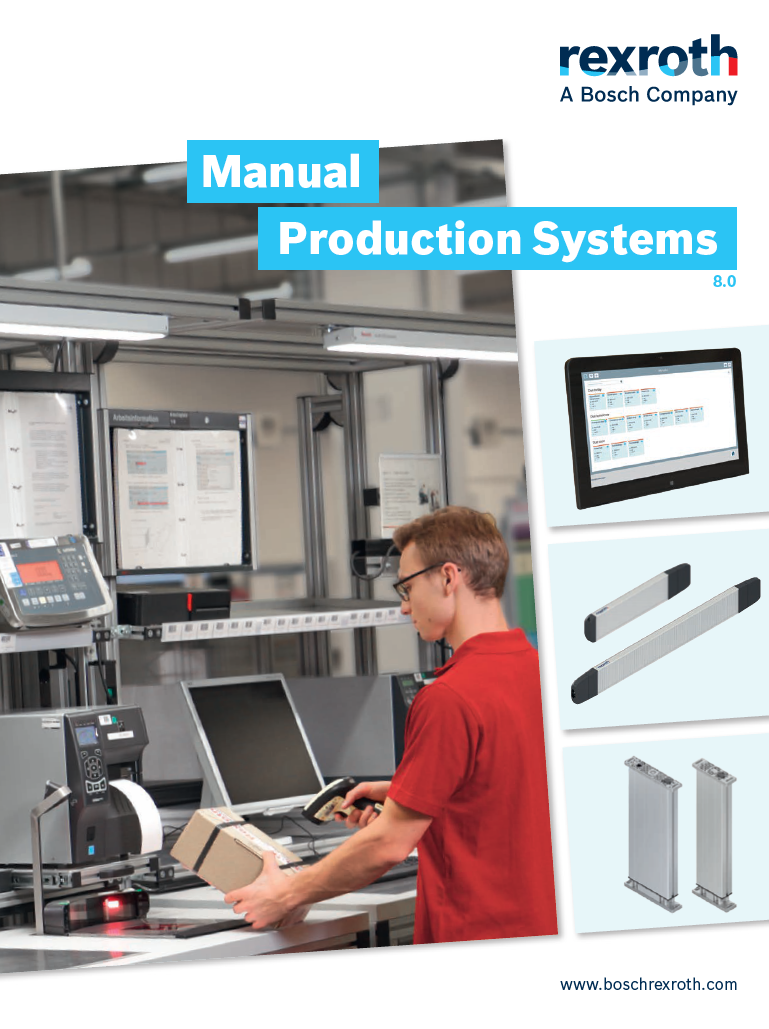

Download your MPS 8.0 catalog here:The main concern of modern production is how to avoid waste. The MPS Manual Production Systems from Rexroth have been developed strictly in line with aspects for lean production, enabling simple and fast planning and implementation of lean production installations.

The demands on modern, lean production are more than just focusing on individual modules. In fact, an integrated system with a uniform implementation concept comes to the forefront. As Rexroth, this concept is reflected by the MPS philosophy.

Products Based on the three pillars of the Manual Production Systems, covering workstations, material supply and linking, you can create for example workstations, as well as entire production lines. Those can be quickly adapted to your work content and executed in an extremely efficient manner, avoiding waste in line because of the ‘lean’ principles.

Torfsconstruct Bosch Rexroth Service Center Torfsconstruct will guide you throughout the entire lean production process. Using our MTpro planning software, we assist you throughout the entire implementation process.

The processes Short delivery times and process flexibility enable you to make your thoughts on lean production a reality without any waste.

ESD protection Electrostatic charges develop as a result of electric charging that is generated by friction on various materials or by induction in electric fields. They can then discharge at the workstation and damage or destroy sensitive components. Bosch Rexroth’s ESD program offers a large selection of products to protect your products from damage caused by electrostatic discharge.

Ergonomics An ergonomic workstation design plays a decisive role in reducing waste during production. From an ergonomic aspect, the main focus is on the worker. This is why these workstations are designed to fit each worker and not the other way around.