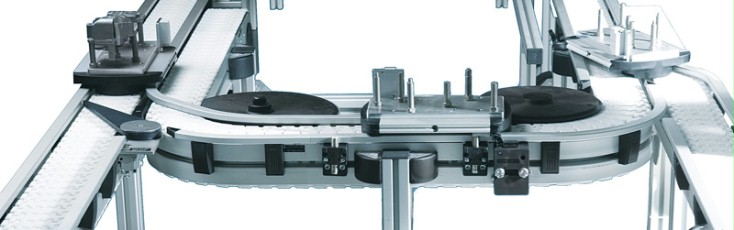

VarioFlow Chain Conveyor System

VarioFlow Chain Conveyor System

Superb Performance — Unbeatable value

The basic facts make Varioflow, the chain conveyor system from Rexroth, a compelling new option: It is more economical than other chain conveyor systems and offers substantially better performance.

Extreme load capacity:

Its extraordinarily stable chain allows VarioFlow to achieve chain tensile forces of up to 1,250N. The nearly closed chain surface allows even small components to be conveyed without compilation. An extensive range of conveyor modules provides solutions for the most diverse conveying tasks.

Adapts quickly to any task:

An outstanding VarioFlow characteristic is easily it adapts to specific tasks. VarioFlow masters even the most difficult layouts where other conveyor systems fail. On-site adaptation to complex applications is a breeze, and usually requires the exchange of just a few components, such as the chain or the slide rails.

Comprehensive range:

Whether for vertical or horizontal conveying, the wide selection of standardized curves and arcs opens up new planning and implementation possibilities.

A wide range of conveyor chains:

Different products require different chain types. VarioFlow has many styles to choose from:

- Flat chain

- Cleated chain

- Steel-plated chain

- ESD chain

- Static friction chain

- Accumulation roller chain

- Roller cleated chain

- Universal chain

Set your own speed:

Besides the conveyor layout with vertical and horizontal curves, curve wheels, lateral guides, and profiles, the drive concept is also modular: Variable speed drives feature compact designs and are equipped with an overload coupling. Motors with integrated frequency inverters permit infinite on-site speed adjustments to meet your specific requirements.

Lateral Guide Program for Chain Conveyor Systems:

Rexroth has expanded the comprehensive range of products in the VarioFlow and VarioFlow S chain conveyor systems with a new lateral guide program. It consists of supports, clamping heads, profile rails and profile cover rails, which guide the most varied parts in numerous standard and customized applications.

Application examples:

Whether metal workpieces, electronic components, cosmetics. Whether food or packaging industry – VarioFlow is the right conveyor system for all cases!

Benefits at a glance:

- Modular conveyor system, compatible with the Basic Mechanic Elements provided by Bosch Rexroth

- Efficient FMS soft planning software, based on Autocad

- Fast, smooth assembly due to pre-engineered modules

- Economical product hardware

- High chain tensile strength

- Modular, compact drives for conveyor speeds from 5 to 66m / min

- Seven sizes, 65, 80, 90, 100, 160, 240 and 320mm system width

- A range of chain styles for optimum transport of any material

- Large selection of curves and arcs for individual conveyor layouts

- Frequency inverter to match the conveyor speed to the application

- With oil, dirt, or shavings – VarioFlow can also be used in tough environments